Turbocharger Overview

Definition of a Turbocharger

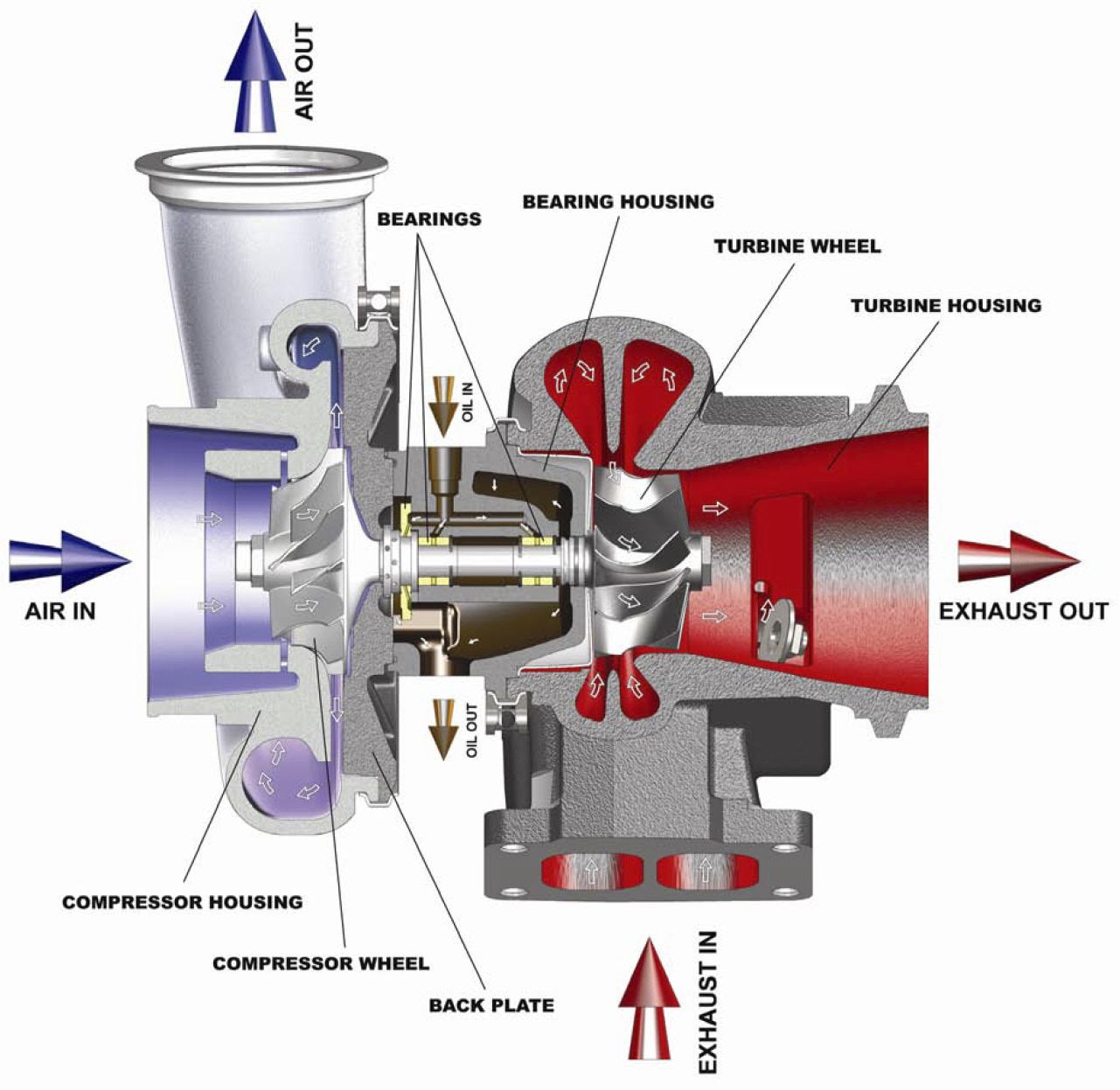

A turbocharger (Fig. 1) is a radial fan pump driven by the energy of the exhaust gases of an engine. Turbochargers consist of a turbine and a compressor on a shared shaft. The turbine is a heat engine in itself. It converts the heat energy from the exhaust to power, which then drives the compressor, compressing ambient air and delivering it to the air intake manifold of the engine at higher pressure, resulting in a greater mass of air entering each cylinder.

Objective & Benefits

The objective of a turbocharger is to improve upon the size-to-output efficiency of an engine by solving one of its cardinal limitations. A naturally aspirated automobile engine uses only the downward stroke of a piston to create an area of low pressure in order to draw air into the cylinder through the intake valves. This ability to fill the cylinder with air is its volumetric efficiency. Because the turbocharger increases the pressure at the point where air is entering the cylinder, a greater mass of air (oxygen) will be forced in as the inlet manifold pressure increases. The additional oxygen makes it possible to add more fuel, increasing the power and torque output of the engine while reducing emissions.

Structure of a Turbocharger

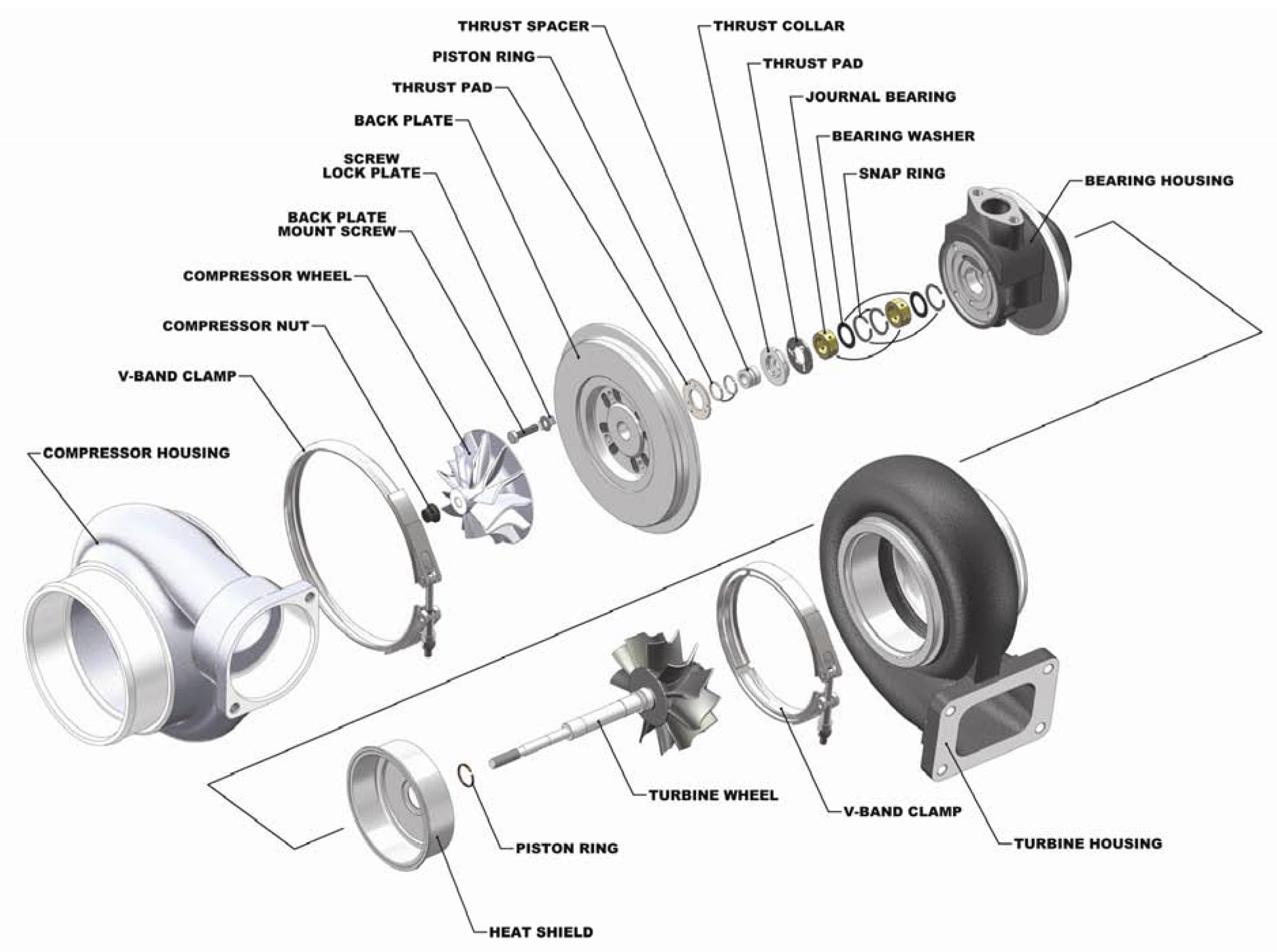

A typical turbocharger assembly consists of the components shown in Fig. 2 below. There are many variations of this assembly with minor differences. Some turbocharger assemblies will contain supplementary components such as a ball bearing cartridge, a variable nozzle turbine (VNT) assembly, or a wastegate.

How a Turbocharger Works

Installation Procedures

Before a New Turbocharger is Installed

It is important to inform the customer of the analysis results. In most cases, the cause of failure originates from either an installation error (foreign material, etc.), improper vehicle systems (oil lines, etc.), or improper operation of the vehicle (hot shutdown, etc.). Ensure the cause of failure is fixed and/or the customer is educated about the cause of failure prior to installing a new turbocharger to avoid a repeat failure.

Steps for a Proper Turbo Installation

- Start the turbo installation by removing old gasket material from the exhaust manifold and pipe. The surfaces of the flange must be clean and have no damage.

- Remove all plastic or foam blanking plugs from the turbo.

- Position the turbo onto manifold or engine block using the correct new gasket or O ring, and then reconnect the exhaust pipe.

- Tighten all nuts and bolts to the correct torque.

- Pay special attention to oil feed and drain lines, which must be totally clean and have no damage to ensure unrestricted oil flow.

- Make sure that no flexible hose liners have collapsed internally, and that oil feed line is not too close to any source of heat which may have damaged the oil feed line internally. This is common on some vehicles and difficult to detect without cutting the pipe! We recommend fitting a new oil inlet pipe when installing the new turbo.

- Install oil drain line to the turbocharger, then pour new engine oil into the oil inlet hole of the turbocharger and fit the oil feed line. Spin the compressor wheel by hand a few times – it should spin freely. Note that it is normal to feel some up and down movement of the wheels. Install inlet and outlet air hoses to turbocharger compressor housing and make sure that the connection is airtight.

After Installing the Turbo

- To test, crank the engine for 10 – 15 seconds to prime oil feed without starting the engine.

- Start the engine and let it idle for 3 to 4 minutes to allow for proper inspection of oil, gas and air leakage.

- If any leakage is detected during engine start up, please fix the issue immediately.

- For VNT turbos, please ensure that actuator operates correctly after starting up. During vehicle key-on and start-up, it is normal for VNT turbos to show movement in actuator, vane arm and vane mechanism, and it is also normal to hear a high-pitched noise from electric actuators.

- If no movement is detected, investigate the cause on the vehicle, as the actuator operations were set and tested before it left the factory.

Important Note: The gears in our electronic actuators are “self-blocking”, this means that it is not possible to move the actuator operating arm or the connecting rod manually. Attempting to move these parts with a tool or by hand may break the gears and make the turbo unusable. Damage of this sort is not covered by our warranty.

Finally, stop the engine and re-check engine oil level. It is important to make sure that oil level is between the minimum and maximum levels allowed.

Turbo Prelubrication Guide

Please note this pre-lubrication notice is provided for your technical reference and is not an authorization for repair nor is it meant to be a complete guide to turbo installation or a replacement to common sense.

Turbochargers are close-tolerance, high-precision, high-speed, rotating units with speeds exceeding 100,000 RPMs. The turbine wheel shaft is centered on a film of pressurized engine oil, and if not pre-lubricated correctly before engine start-up the turbo will be destroyed. Scorched, scored, seized, grooved, or melted bearings and or turbine shaft will void any warranty. To avoid dry starting the turbo follow the oiling procedure described below.

- The engine oil, oil filter(s), and air filter(s) must be replaced with new equivalent Items before installing the turbo. Some units have a micro screen filter inside the oil supply fitting that must be replaced as well.

- Note: Don’t forget to inspect air and exhaust inlets and outlets for any obstructions, damage, or debris.

- A new oil supply line is highly recommended due to possible Petroleum Coke (carbon buildup) breaking loose and stopping up oil ports.

Make sure the oil drain line has been cleaned and installed with a new gasket and is completely clear of any obstructions or kinks. Any silicone use will void warranty. Any restriction in oil drainage will cause seal leakage. - Before the engine is started, lubricate the turbo with correct, clean, engine oil. Slowly pour 2 to 3 ounces (50 to 60 cc) of oil into the supply fitting while carefully rotating the turbine wheel by hand. Be patient as it may take a while. DO NOT use compressed air or air tools to turn the turbine.

- Flush/prime the oil supply line by turning the engine over but not letting it start up. Do this until the supply line has unrestricted free flow of oil. DO NOT hold compressor wheel to flush / prime oil line. Any air left in the oil supply line can cause turbine shaft and or bearing damage and void warranty.

- After completing the install, let engine idle at a low idle for 3-5 minutes.

For more insights on turbocharger technology, you can join Garrett’s Installer Connect community.

Take the online courses and receive Garrett Installer Connect certificates… FOR FREE!

https://www.garrettmotion.com/turbo-replacement/installer-connect/

Note: when registering make sure to reference Midwest Fuel Injection.

Common Causes For Turbocharger Failure

This section will discuss the four primary causes for turbocharger failure. It is important to note that when a turbocharger fails for any reason, there is almost always secondary (and often more severe) damage caused by the resulting shaft motion. You must look passed the obvious damage to locate the root cause. Note that some “cause of failure” descriptions contain very similar indicators so be sure to read through all prior concluding your analysis.

1. Lack of Lubrication / Contaminated Oil

The lubrication system plays a vital role in extending the life expectancy of a turbocharger by lubricating, cooling, and cleaning the bearings. The shaft and bearings must “float” on a constant, clean film of oil to prevent direct contact with each other which will result in damage. Any lack of oil flow or foreign contaminant (i.e. dirt, sand, or metal shavings) in the oil will cause excess wear and/or scaring on the bearing surfaces. This wear will often increase the clearances between rotating components resulting in excess “shaft motion”. A large amount of “shaft motion” is detrimental to the life of a turbocharger.

Common causes of lubrication failure:

- Low engine oil pressure/level

- Obstructed oil supply / drain lines

- Improper weight of oil

- Contaminated oil

- Fast starts in cold weather

- Hot shutdown (Fig. 6) – Engine is shutoff at high rpm/temp; instant oil flow loss causing overheating

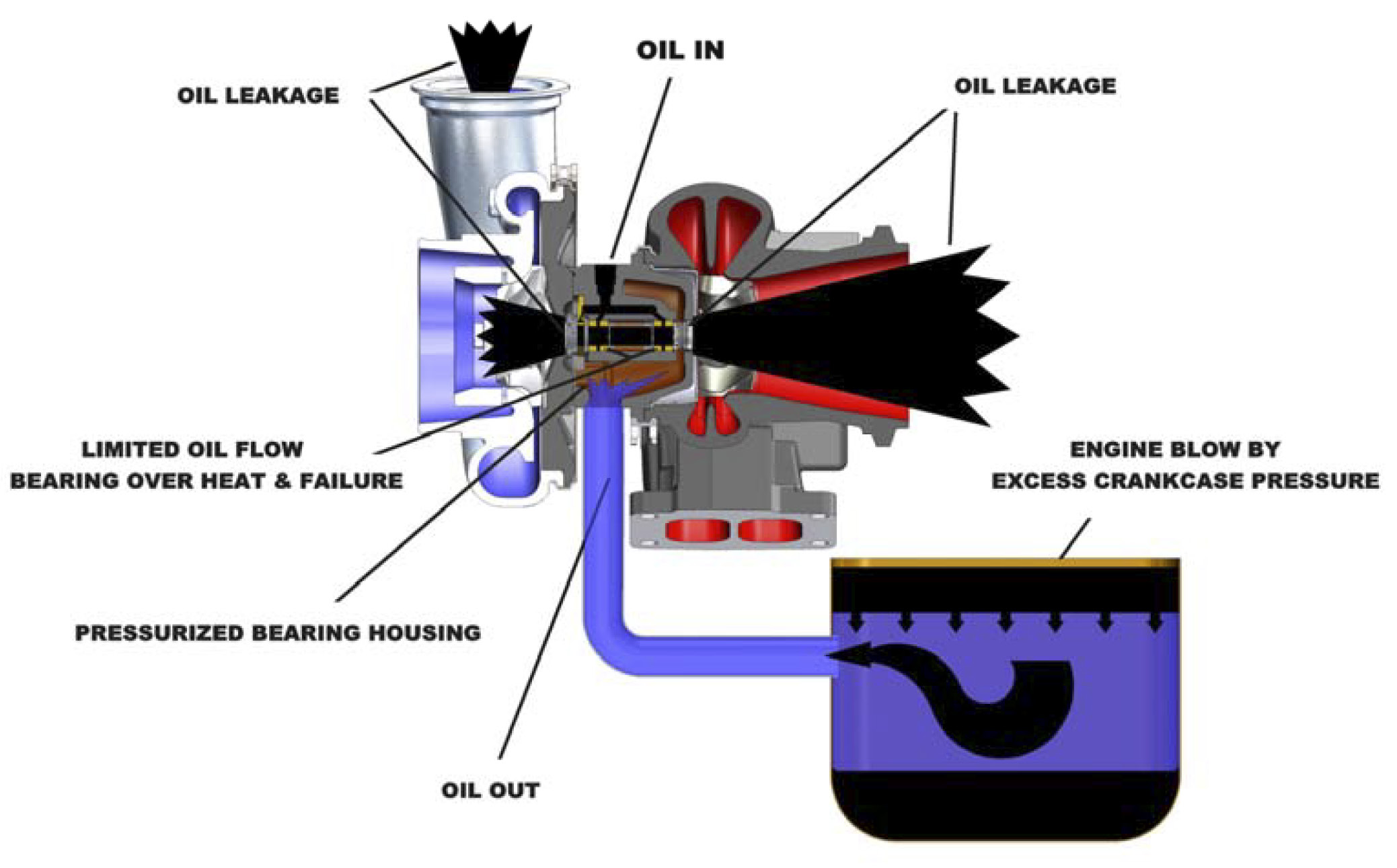

- Engine Blow-by

A. External Lack of Lubrication:

- Occurs when anything exterior to the turbocharger is affecting the oil flow (supply or drain lines, engine blow-by, etc.).

- All thrust & journal bearings as well as the turbine shaft will show signs heat discoloration (Fig. 7) as well as wear from the resulting shaft motion. The wear will appear smooth or “wiped” (Fig. 8 & 9) and should not have any significant scaring (Fig. 10 & 11).

- Unwarrantable: The cause of this failure is external to the turbocharger.

B. Internal Lack of Lubrication:

- Visible when one or more, but not all, of the bearings show the above mentioned wear. This indicates that only one of the oil feed lines have been blocked from either contaminated oil (see below) or a manufacturers defect.

- Warrantable: If there are no signs of contaminated oil.

- Unwarrantable: If there are signs of contaminated oil or “coking” of the oil caused by overheating.

C. Contaminated Oil:

- Occurs when abrasive material such as dirt, sand, or metal shavings enters the oil passages. This is generally easy to notice as the bearings and connecting components will show abnormal grooves and scratches (Fig. 10 & 11). This may also cause a lack of lubrication failure as noted above.

- Unwarrantable: The cause of this failure is related to the installation or oil quality within the vehicle.

2. Foreign Material in Exhaust or Air Inlet

Foreign particles (i.e. Screws, nuts, sand, metal power, broken air filters, etc.) entering the turbine or compressor stages will damage the rotating turbine or compressor blades. Both wheels are accurately balanced to perform at extremely high operating speeds required by their application. If either wheel is damaged in any way, the rotating assembly will no longer maintain its balanced state which will result in severe shaft motion causing almost every component of the turbocharger to fail.

In many cases, this is the most obvious damage to recognize as the compressor or turbine wheel will often show severe damage without removing the housing (Fig. 12 & 13). However, in some scenarios, this is a gradual erosion of the wheel from fine particles such as sand or dirt. In this case, the wheel will display small pits across the vanes or minor wear on the inducer tips.

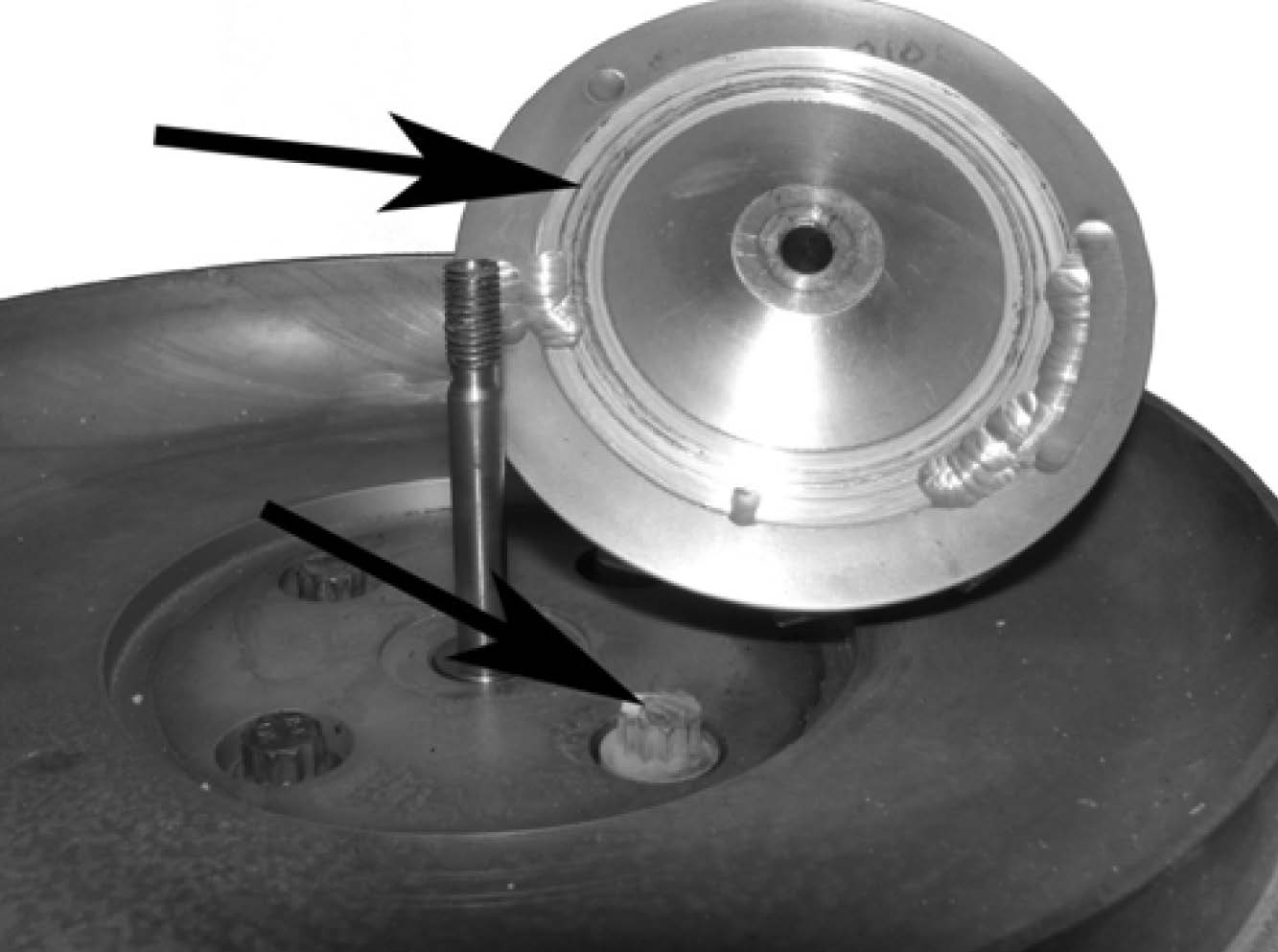

Although rare, this failure may also be caused by the compressor wheel lock nut loosening off and entering the compressor vanes (Fig. 17). This failure originates from assembly if the lock nut was not tightened to the specified torque setting or the Loctite® compound was not applied.

- Warrantable: If the compressor wheel lock nut is the visible cause of failure.

- Unwarrantable: If caused by any other foreign material external to the turbocharger.

3. High Exhaust Temperature

Excessive temperature in the exhaust system will cause the lubricating oil to “coke” in the bearing housing drain annulus at the turbine end (Fig. 14). This causes oil leakage into the turbine housing. Coke and carbon deposits will be visible and eventually damage the back of the turbine wheel and cause abnormal wear on the thrust bearing. High exhaust temperatures can also erode (Fig. 15) and crack (Fig. 16) the turbine housing and/or bearing housing. Excessive heat discoloration of the turbine shaft is usually visible. The piston ring in the turbine side of the bearing housing will often appear relaxed if it has been submitted to these high temperatures.

High exhaust temperatures can originate from several operating conditions shown below:

- Incorrect fuel ratio (high fuel setting)

- Insufficient air supply caused by a plugged air cleaner, etc.

- A leak in the intake manifold or piping

- Excessive exhaust restrictions

- Plugged aftercooler core

- Unwarrantable: Unless incorrect compressor or turbine housings were assembled

4. Defective Workmanship or Material

While these occurrences are rare, the visible evidence is often easy to recognize. Some examples are displayed and explained below.

- Warrantable: If the defects originate from the manufacturer.

- Unwarrantable: If the defects originate from the installation.

Common Failure Diagrams

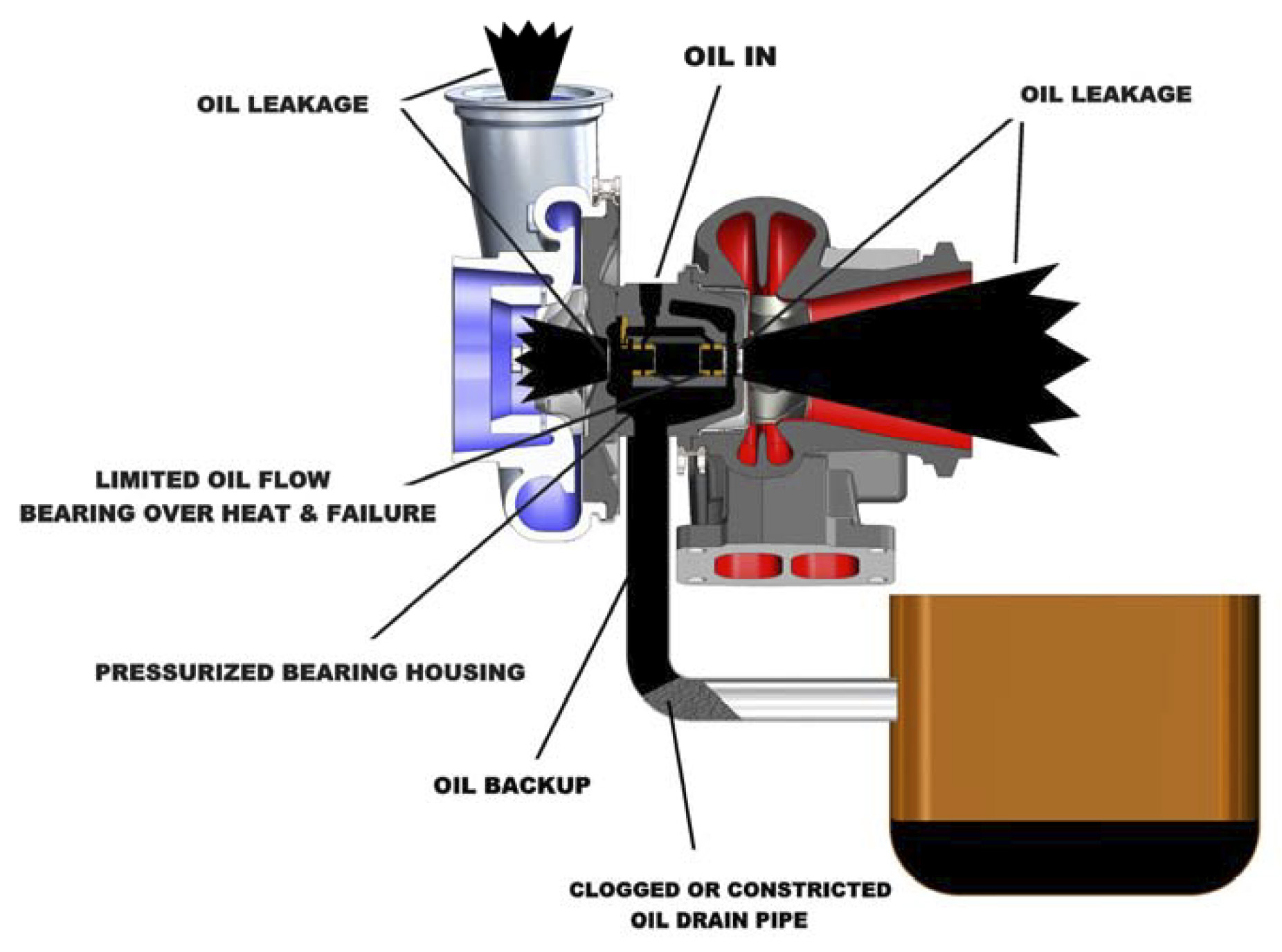

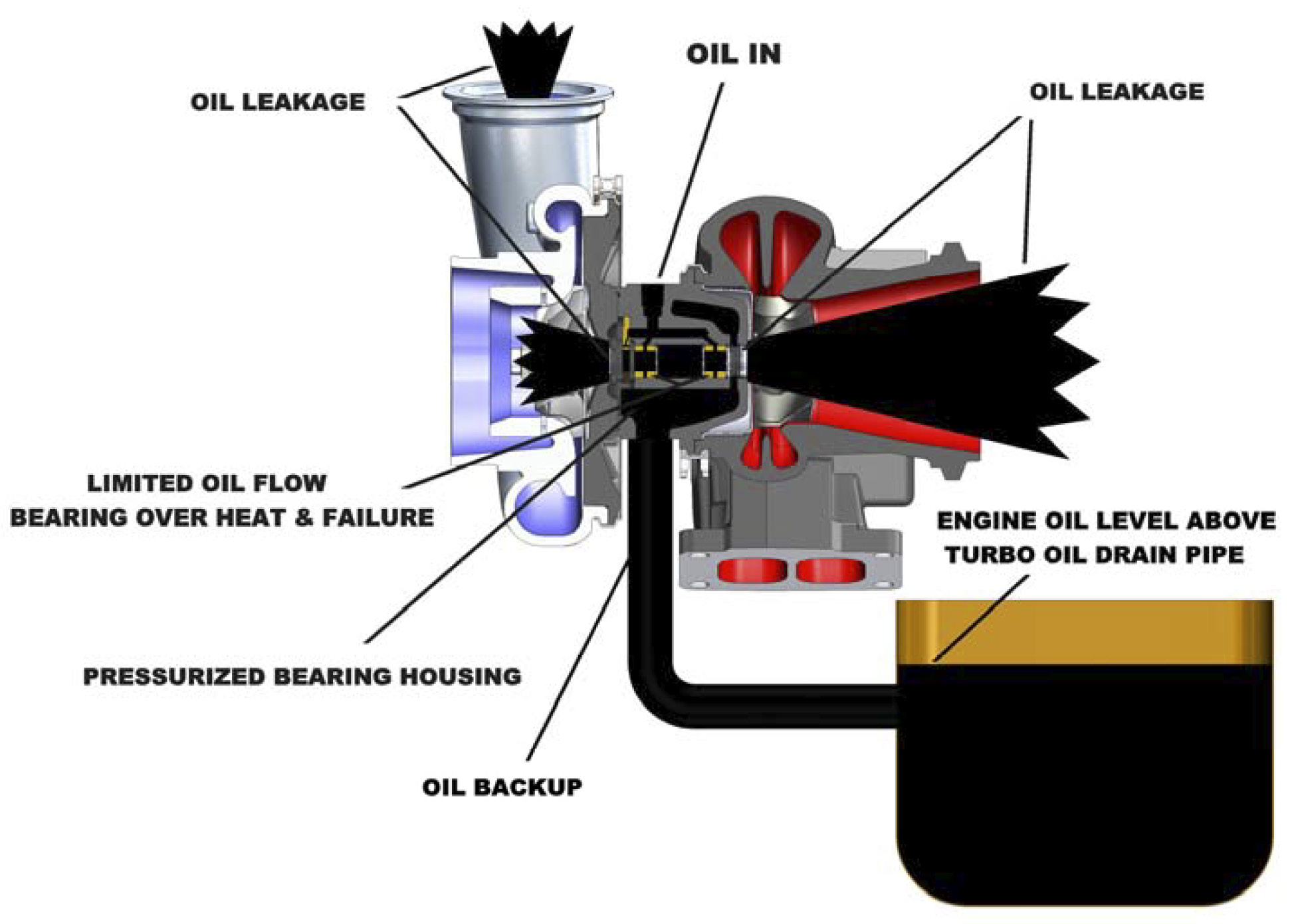

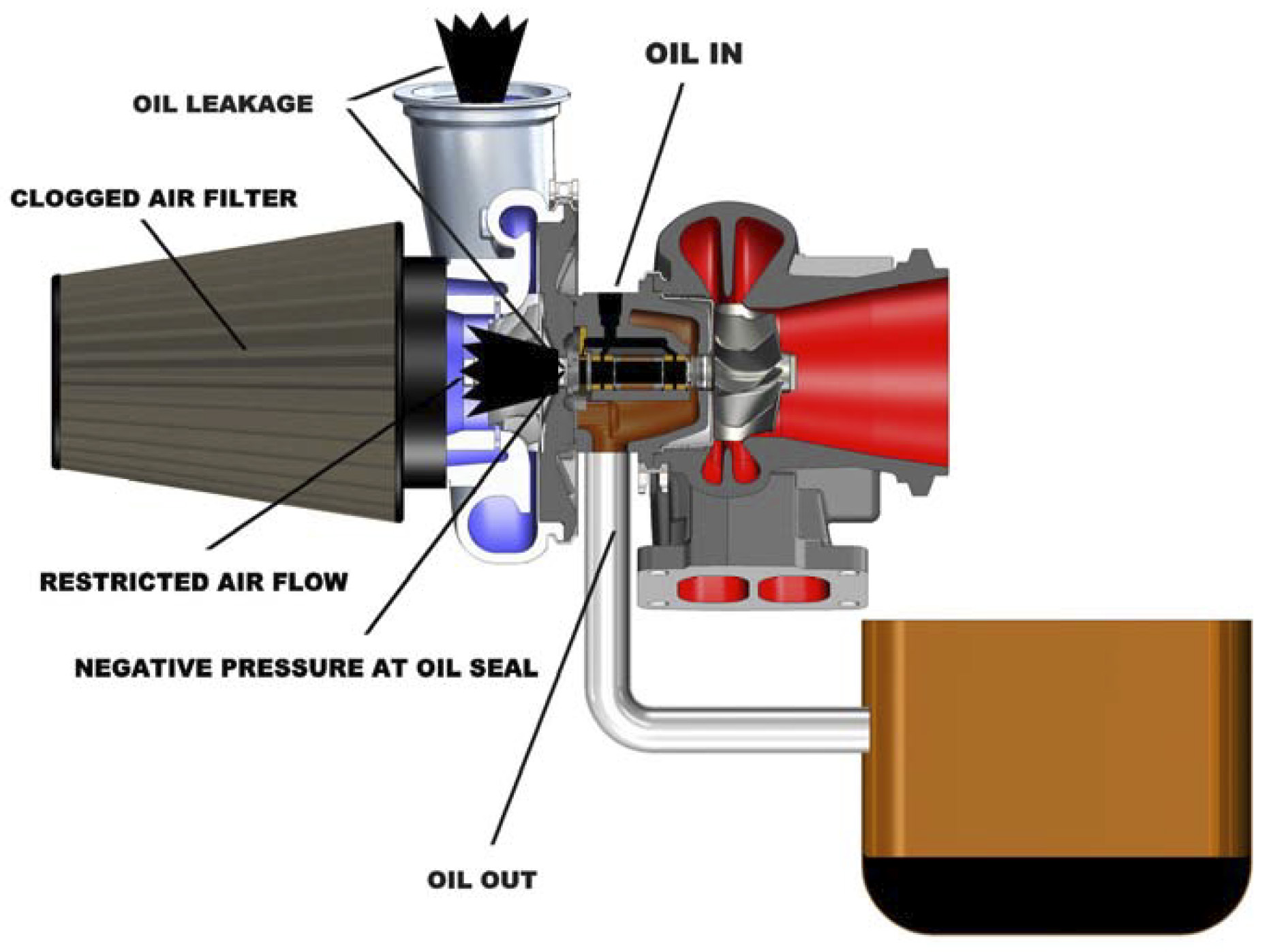

Below are four examples of Turbocharger failures due to improper installation or vehicle systems.

Fig. 20: Engine Blowby – Increased crank case pressure causes flowing oil to squeeze out of the piston ring gaps and also reduces the amount of oil flow to the bearings causing failure

Fig. 21: Clogged Oil Drain Pipe – Oil cannot flow and pressurizes the drain area causing oil leakage and bearing failure

Fig. 22: Oil Level Too High – Any minor pressure in the crank case will prevent oil from flowing which pressurizes the drain area causing oil leakage and bearing failure

Fig. 23: Clogged Air Filter – Reduced air flow in the compressor inducer will create high vacuum area which will pull oil into the compressor side of the turbocharger

Periodic Maintenance & Inspection

In most cases, the damage severity of turbocharger failure can be greatly reduced by performing routine inspections during normal vehicle maintenance. Start by removing the turbine and compressor housings and inspect the state of the wheels and housings. If there are no abnormalities, do not disassemble further but rather inspect the bearings by manually turning the wheel assembly. The wheels should turn freely without any hindrance. You can also place a dial gauge on the wheel assembly to measure the axial play. If this play exceeds the maintenance standards in the service manual, the turbo should be removed and fully inspected.

Summary

There are many factors that can greatly reduce the life of a turbocharger. This text was designed to serve as an educational guide to improve our customer’s knowledge. In most cases, turbochargers fail due to improper use or maintenance by the end user. It is hoped that better informing our customers will reduce the time required to get this information to the end user and also reduce costs related to warranty returns.